Exploring the Distinct Features of a WPC Door Factory’s Production Approach

In the modern door manufacturing industry, WPC Door Factory stands out due to its commitment to innovation, durability, and eco-conscious production methods. WPC, or Wood Plastic Composite, is a material that combines the strength of wood with the resilience of plastic, making it an increasingly preferred choice for both residential and commercial applications. Factories dedicated to WPC door production are not just suppliers—they are central to redefining what durable, low-maintenance, and sustainable door solutions look like.

One of the defining features of a WPC Door Factory is its use of advanced composite technology. Unlike traditional wooden doors that may suffer from warping, cracking, or termite damage, WPC doors offer resistance to moisture, insects, and general wear. These qualities stem directly from the composition process at the factory, where wood fibers are uniformly mixed with thermoplastics and extruded under high temperature. This results in a dense, stable material that does not require frequent repainting or sealing, making it ideal for high-humidity or outdoor environments.

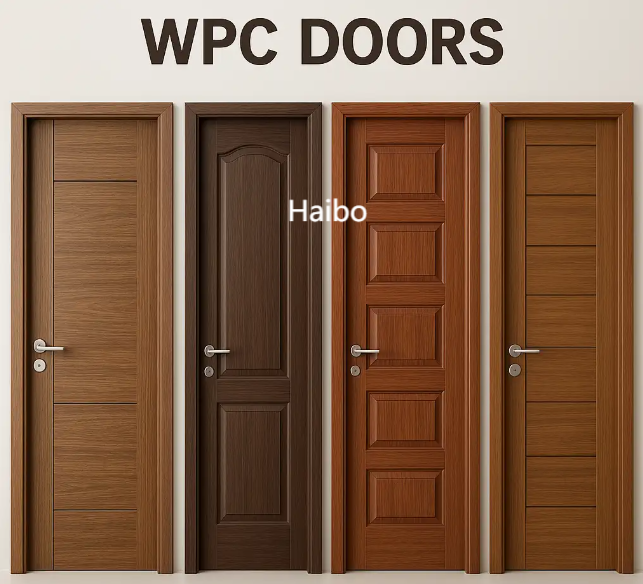

Another element that makes WPC Door Factory operations distinctive is the attention to design flexibility. Because WPC can be molded into various patterns and finishes, it allows for a wide range of visual styles—whether mimicking natural wood grain or incorporating sleek modern textures. The factory's ability to create doors that complement contemporary, traditional, or minimalist interiors reflects its versatile production capabilities. With minimal surface preparation, WPC doors can even be directly laminated or UV-coated, giving them long-lasting aesthetic appeal.

Environmental awareness is also a major differentiator. WPC Door Factories often focus on recycling wood waste and utilizing eco-friendly thermoplastics, reducing their reliance on virgin resources. Compared to solid wood doors, WPC options significantly lower deforestation impact, and their longer lifespan helps reduce the need for frequent replacements. Additionally, many factories have shifted toward energy-efficient production lines, aiming to further minimize their carbon footprint while meeting increasing global demand.

Durability and low upkeep are core selling points, but what truly enhances the appeal of a WPC Door Factory is its ability to serve diverse applications. From bathroom and kitchen doors to school and office installations, the material adapts easily without compromising structure or style. As builders and developers seek alternatives to traditional wood and metal options, the reliability and performance of WPC doors become even more valuable—especially in projects that prioritize both cost efficiency and longevity.

What makes a WPC Door Factory truly unique is its seamless integration of strength, sustainability, and style. The factories not only deliver functional doors but also reflect a broader shift in how we design living and working environments. Their contributions go beyond product supply—they influence design standards and support greener building practices. To learn more about high-quality WPC door solutions, visit https://www.haibodoor.com/news/industry-news/inside-a-wpc-door-factory-what-is-a-wpc-door.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness