Yd-purification Air Shower Factory for Cleanroom Workflow

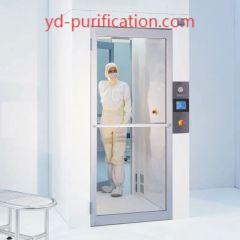

As a professional Air Shower Factory, yd-purification develops entry control systems essential for maintaining environmental protection during cleanroom access. These air-enclosed units function as self-contained decontamination tunnels, using concentrated airflow to remove particles from garments and surfaces before individuals or materials enter a contamination-sensitive zone.

Maintaining cleanroom classification standards requires more than filters and room design—it depends on how personnel move between zones. Air showers are critical transition points where contamination risks are actively controlled through kinetic airflow. With targeted nozzles and directional sequencing, the system dislodges contaminants efficiently while ensuring that high-speed airflow does not compromise comfort or operational flow.

Each unit is constructed using corrosion-resistant panels, usually stainless steel or powder-coated steel. Transparent or solid door options are available, and the control panel can be configured to manage cycle times, airflow strength, and entry authorization. Standard air showers feature HEPA filters for airflow purification, combined with programmable locking to ensure complete cleaning cycles before access is granted.

The system is suitable for clean production workshops, biopharmaceutical environments, and semiconductor assembly lines. Depending on room layout, showers can be configured as single-door, double-door, L-shaped, or tunnel-style passages. The modular structure allows installation into new or existing facility architecture without large-scale remodeling.

Key Technical Attributes:

|

Feature |

Specification |

|

Outer Frame |

Stainless steel / powder-coated steel |

|

Air Velocity |

≥20–25 m/s (adjustable) |

|

Filter Type |

HEPA (H13) / ULPA (U15) |

|

Entry Options |

Manual / automatic sliding or swing door |

|

Control System |

PLC-based, touchscreen available |

|

Integration |

Compatible with interlock doors and ID systems |

Beyond personnel control, the system supports the transition of tools, carts, and clean containers, keeping material movement aligned with the same contamination prevention strategy. Its reliability stems from tested airflow mechanisms, sealed chamber design, and adaptable configurations.

The ability to integrate into broader cleanroom infrastructure is what positions this system as part of the long-term facility logic. Whether your project is under construction or updating existing zones, a coordinated decontamination channel becomes an essential tool of precision control.

To explore dimension options, specification support, or architectural matching, visit yd-purification.com and engineer your entry system from the inside out.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness